Aluminium moulds

We design and manufacture aluminium moulds:

From fusion

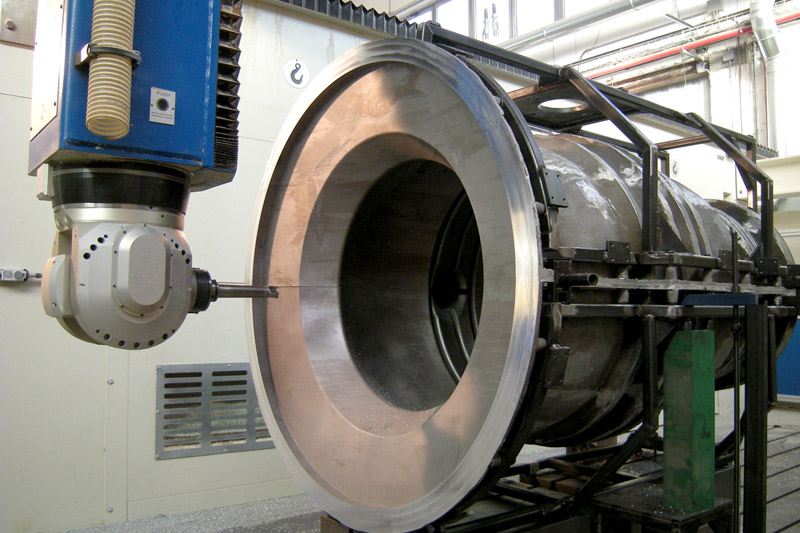

From CNC reworked fusion

Milled from solid with CNC machines

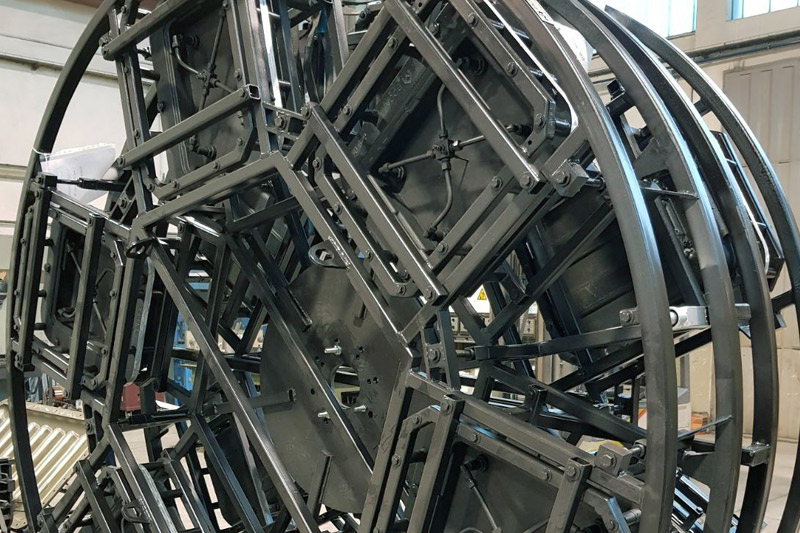

Boca starts working on the aluminium mould right from the model, manufactured in our modelling department or by our CNC machines, merged in our exclusive foundry up to the final processing made using state-of-the-art 5-axis machinery.

Boca’s qualified personnel handle each individual processing stage, thus guaranteeing high quality and total control of workflows

Attention to detail

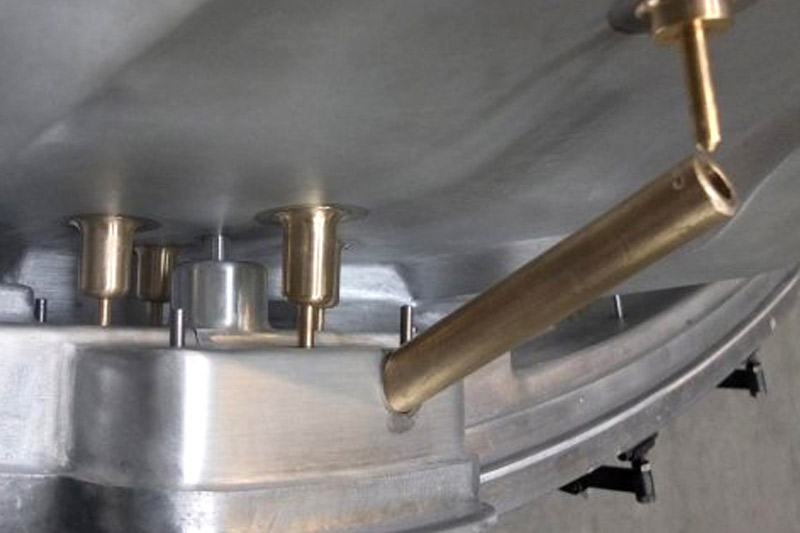

Each fine detail of the mould is covered to ensure not only high performance and ease of use, but also perfect functioning over time.

Each moving part is transported on steel ferrules, to prevent it from wearing during its life cycle. Copper or brass are used in place of aluminium when greater thermal conductivity or greater resistance to impact wear is required.

Each handle and each standard component is designed to be easily replaced in the event of wear or accidental breakage.

Every detail is taken care of to guarantee maximum productivity. In order to maximise the mould’s functionality and the yield of the moulded product, Boca manages customised requests and can provide cutting-edge solutions resulting from constant technological research.