Rotational moulding

Boca is a leading company in the moulding sector

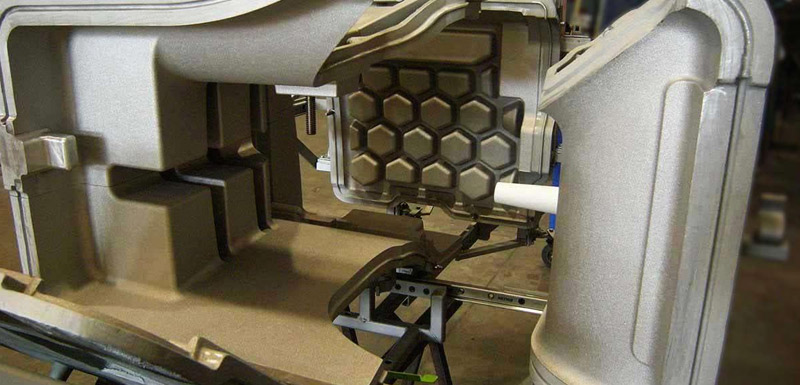

and designs and manufactures rotational moulds in CNC-milled aluminium, cast aluminium and prototype composite moulds.

Our thirty-year experience in this sector means we can deal with any project, from developing an idea to engineering a product.

Relying on Boca to have a mould manufactured means using a partner with an in-depth knowledge of the materials and processes, and has the latest technologies to implement them.

Boca has always produced guaranteed high quality moulds that are easy to use.

The rotational moulding process

Rotational moulding is a transformation process of plastic that produces hollow bodies.

The advantages of rotational moulding are their simplicity of use as well as the minimum investment in machines and moulds with the possibility of achieving large products without internal tensions.

Having efficient, ad hoc designed moulds is essential for achieving a good product.

Rotational-moulded products have successfully entered the agricultural, car, urban furnishings, food (beverage and food), automobile, chemical, construction, ecological, gardening, medical, nautical, road, health industries and many others.

Thanks to the advantages of this technology, its development and diffusion, it is still growing rapidly, combining both the needs of designers for harmonious shapes and the technical needs of innovative products.

The added value of a rotational Boca mould

A mould at Boca is followed every step of the way by expert and dynamic personnel.

The Boca technical department can redesign products made with obsolete technologies, creating harmonious shapes as well as being optimised for rotational moulding.

Finite element calculations (FEM) allow you to simulate the behaviour of the rotational moulded products in their daily use even before they are put to use.

the machines, experience and available technologies guarantee the perfect implementation of the designed moulds.

Our services include testing the moulds before delivery with the production of PE samples to verify the perfect functionality of the mould itself.

BOCA’s flagship is undoubtedly their after sales assistance. Our customer is never overlooked. Solving any problems is supported both in the design and, where necessary, in the after-sales service

Thanks to our collaboration with major manufacturers of rotational moulding machines, we can measure and position the customer’s moulds for their maximum yield in the machine.

BOCA can design and produce ad hoc moulds, “stitched” around the customer’s machines, making the most of the measurements and weights that can be supported.

We can advise on how to economise on the product in the future stage of moulding.