Options

Boca designs and manufactures products and technologies to improve the performance of the moulds and the quality of rotational moulded products

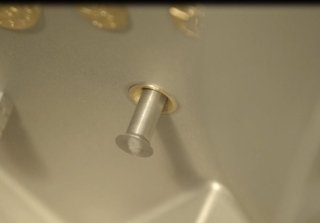

Drop Box

The drop box is a thermally insulated container fitted to the moulds to introduce polymer powders during the moulding cycle.

It is mainly used to produce parts with different materials between inside and outside, or as part of the design to obtain parts with different coloured layers.

The drop box is fitted directly onto the mould and is operated pneumatically by the machine control.

Boca SRL manufactures various sizes of drop boxes depending on customer needs.

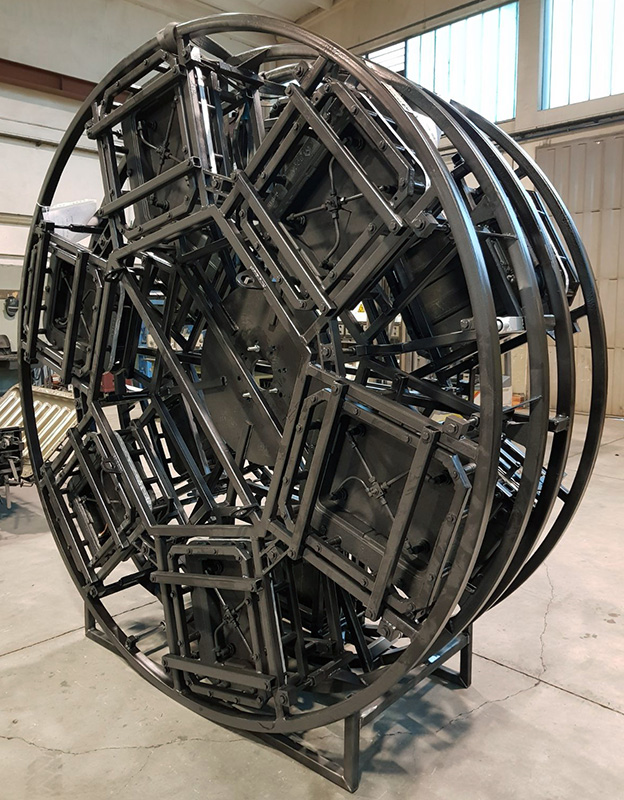

Spider

Space and machine operating times to increase production volumes need to be optimised in order to be competitive in the production of plastic products.

To satisfy the needs of the moulders, it designs and manufactures made-to-measure mould spiders for customer machines.

This makes it possible to simultaneously mould a series of moulds, increasing production volumes and reducing the mould opening and closing times.

We design and manufacture whole or separable spiders with handle, screw or centralised closures.

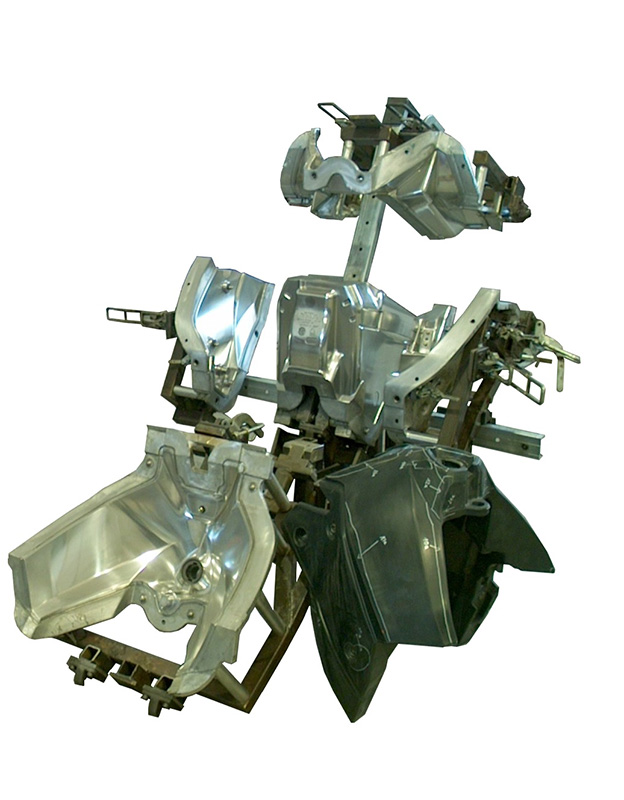

Mould Handling

Boca can design and manufacture moulds with openings guided by trolleys on sliding rails.

This precaution avoids having to dismantle and reposition the mould parts, as they remain tied and transported by the supporting structure.

The advantages of these solutions can be found in the increase in mould productivity, as well as a drop in the risk of damage to parts when the piece is being assembled and the elimination of the risk of incorrect repositioning of mould parts.

Boca S.r.l. designs and produces linear or book-shaped sliding rails for aluminum or sheet moulds with moving parts fitted on bearings, in order to guarantee maximum smoothness on even heavy objects.

Core formers

Boca S.r.l. designs and manufactures core formers with materials of varying origin, for double-walled products.

The core formers are made with CNC machines and can be equipped with manual or pneumatic closures.

Pneumatic Handles

It is possible to automate the opening and closing of the moulds using pneumatic handles, which guarantee greater mould productivity.

All the handles can be simultaneously opened and closed using the pneumatic handles, both manually and automatically from the machine PLC

Several versions are available

Mould extractors (blower)

It may be the case that, with complex items, the geometry of the mould makes it difficult to extract the product.

To deal with this problem, Boca has designed and produced a solution that is easy to install and use.

It is a pneumatically controlled spring valve to be installed on the mould surface,

During extraction, the aid of these valves allows you to create a thin layer of air between the mould and the product, making it possible to extract it.

This technology is used on new moulds where it is assumed there is a need for it and can be installed (retrofit) on any existing mould